ORGAN MAINTENANCE

I am often asked what maintenance is required on an Allen organ. Should an organ be inspected, checked and tuned on a regular basis?

Firstly, one of the advantages of a digital instrument is that it never needs tuning. Unlike a pipe organ which will vary in tuning with the temperature of the season, the digital organ remains in tune forever.

However, there are other items that wear and may need attention over time. In a nutshell, anything that moves will wear, and will eventually require service. The most obvious of the items that move are the keys - and ultimately they will become sloppy, especially around the centre of the keyboard. Allen keyboards are of quality manufacture, and rarely is any adjustment required. Probably by the time the keyboard wears out, it is time to consider a new instrument.

The next most obvious of the moving items on an organ are the tab stops or draw knobs. Draw knobs on older instruments occasionally show signs of sticking. The best way to keep these in good condition is to play the instrument regularly. However, on a service, these may require cleaning and lubrication. Not so obvious are the electrical contacts that function when a tab stop or draw knob is operated. On instruments more than about thirty years old, the electrical contacts consist of two phosphor bronze contacts which mate together. Over time these contacts can tarnish and the stop does not always work or it sounds scratchy when the stop is operated. Again, playing the instrument regularly is the best way to keep the contacts clean. About thirty years ago, Allen changed to using sealed reed switches on all keyboards and stop tabs. This type of switch is far more reliable and gives very few problems.

Thumb pistons and toe studs also have contacts behind them, which if not operated regularly, become less reliable over time. Again, regular playing is the best way to keep these items functioning well.

The expression pedals are another moving part on the organ. To vary the volume on an Allen organ, there is a specially shaped plate which moves between a lamp and a light dependent resistor as the pedal is pressed. Thus there is no moving part directly controlling the change in volume. However, there are a couple of nylon washers which provide friction to the movement of the expression pedal, and these washers wear over time and should be replaced eventually.

Any other control, switch or relay will also have some moving parts but failure of these items is rare.

The other parts in an organ which are continually moving - even though it is not so obvious - are the loudspeakers. A loudspeaker consists of a cone shaped piece of card, which vibrates to produce the sound. Parts of the speaker are manufactured from rubber, and over time, the rubber deteriorates. The degradation of the speaker is gradual over time, but as it happens the sound of the organ slowly deteriorates. Our experience has been that speakers last about fifteen years, although it is usually closer to twenty years by the time we receive a phone call to say "The organ does not sound right". It costs about $1200 to replace the speakers in each speaker cabinet, and this cost should be budgeted into the maintenance costs of the organ. At less than $100 per cabinet per year, it is still a fairly insignificant cost.

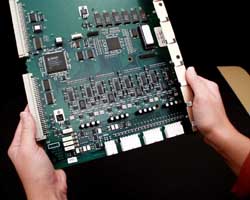

Failure of the electronic sound generation system in an organ is rare. Since the introduction of the Renaissance/Quantum series of organs in the late 1990's, the number of service calls we have had due to failure of electronics in these organs can be counted on one hand. The reliability of the modern Allen organ is extremely high. Equipment is burnt in and tested extensively before it leaves the factory.

On organs which are now forty or more years old, we are beginning to see failure of some of the capacitors in the power supplies. Failure of other electronic boards and equipment does occasionally occur but it is generally random and unpredictable. The Allen Organ Company has the philosophy of keeping enough parts to be able to service any operational organ, and when parts do run out, they have redesigned circuits to operate using available parts so as to keep an organ working.

One other item that degrades over time is batteries. Organs with a capture action system generally have batteries keeping the settings in memory. If you have an organ with a console controller, make sure you check the console controller display for a "Replace Battery" message when the organ is first turned on. On organs without console controllers, if the power LED flashes for about six seconds when the organ is first turned on, then the battery needs replacing.

Maintenance of an Allen organ is almost non-existent. Your instrument will operate reliably and give many years of faithful service. However, in the event of needing service in Western Australia, send Rodney Raymond an email or call on 9310 2838 and we will be pleased to assist.

![]()